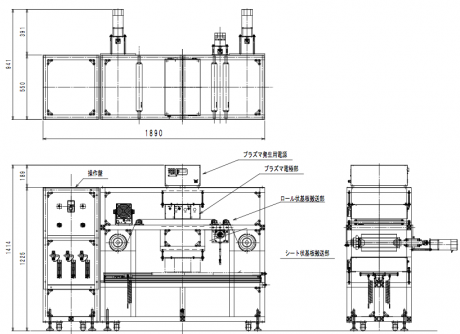

Air-pressure Plasma Processing Apparatus

This unit can process any rolled or sheet work.

The air-pressure plasma processing can even be implemented into existing lines with only a processing head.

Features

The air-pressure plasma processing apparatus allows continuous roll-to-roll surface processing with film substrates.

This unit can also provide sheet-shaped work processing.

The processing head can be mounted easily in existing equipment due to the small size.

Specifications

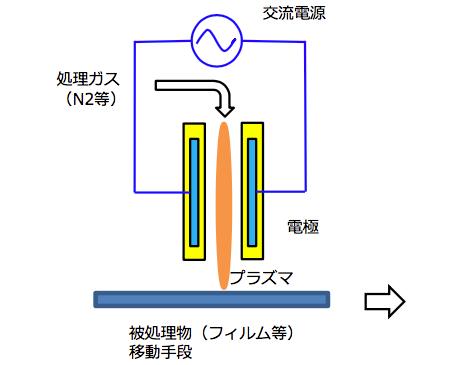

| Processing Method | Dielectric barrier discharge (remote plasma) |

|---|---|

| Substrate conveyor | Roll-to-roll (3-inch paper tube support; Maximum winding diameter: 150 mm; Feeding speed: 1-15 m/min)

Vacuum suction table (330 mm × 410 mm; Feeding speed: Up to 15 m/min) |

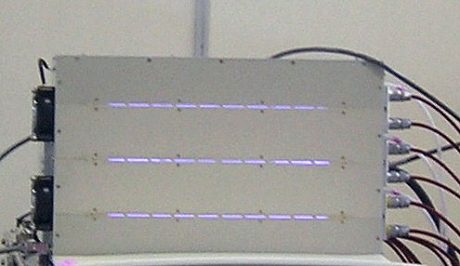

| Plasma Irradiation Rate | 330 mm × 3 Lines |

| Power Source for Plasma Production | Input: 3-phase 200V; 50-60 Hz; Power Consumption: 1.5 kVA |

| Gas Injection System | Massflow controller (N2 standard; other gas options are available) |

| Operation System | Manual operation |

| Utility | Power source of operation panel: Single-phase 100V/500 W (Max.)

Air Pressure: 4 kgf/cm2 or higher (injection for vacuum suction table) N2 gas MIN40SLM/line Exhaust equipment is required depending on the type of gas to use and the operation conditions. |

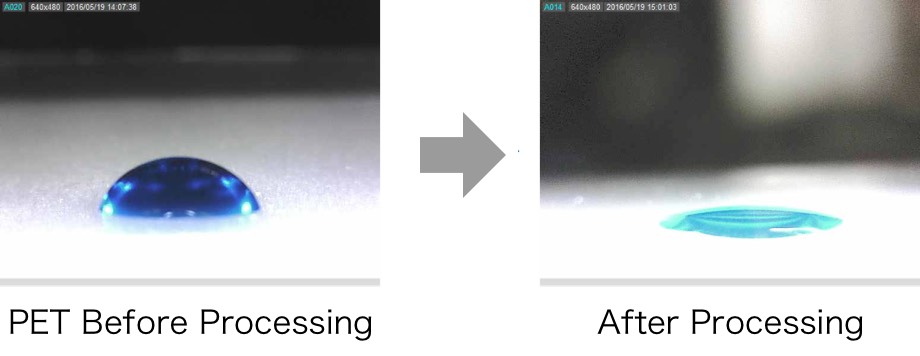

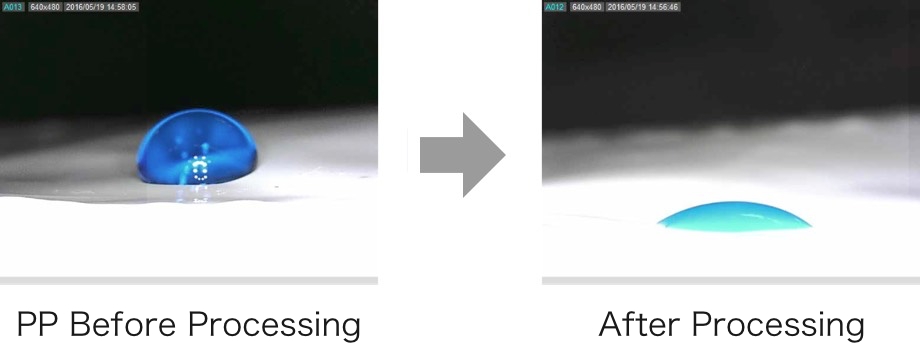

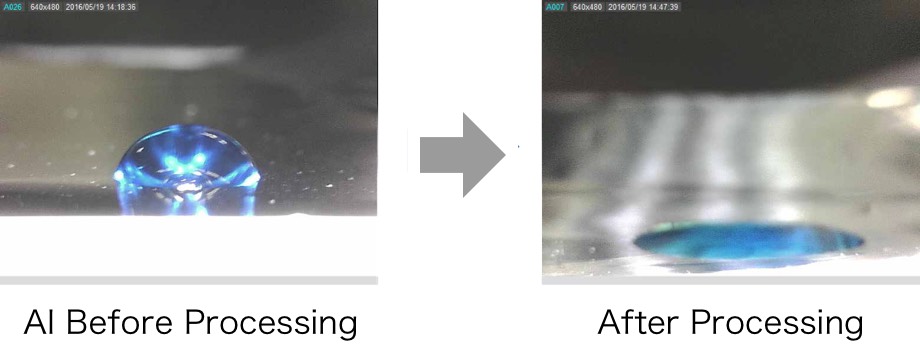

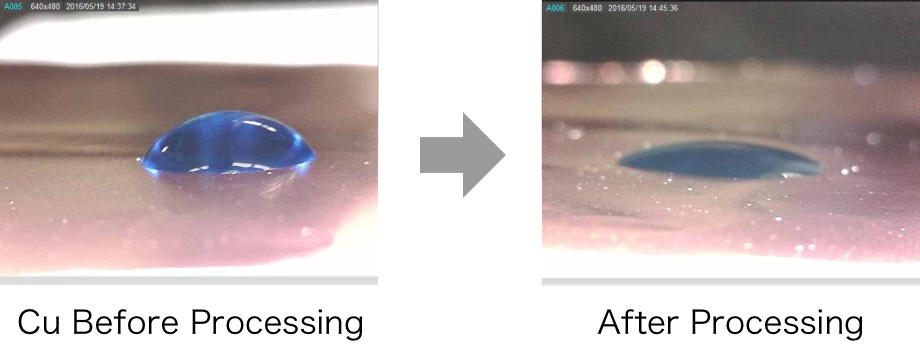

Processing Example